From paper mills to packaging lines, flat belt drives remain the backbone of industrial motion. Explore their advantages, key applications, and simple maintenance tips that keep your systems running longer.

Even with all the new technology in modern machinery, some classics never fade and the flat belt drive is one of them.

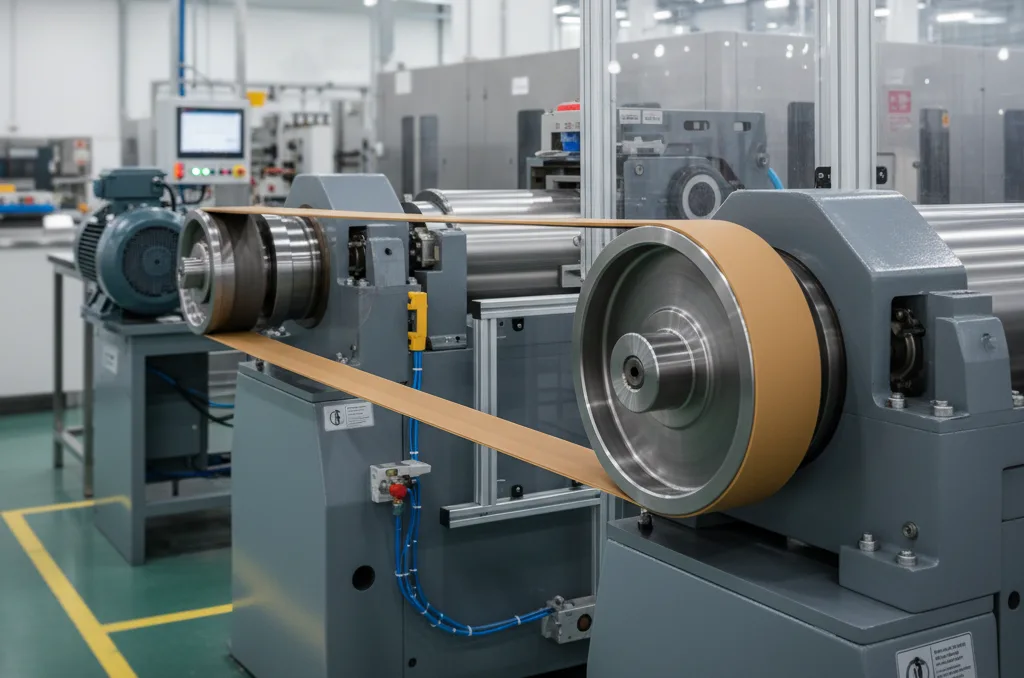

These belts quietly keep factories, workshops, and small machines running by transferring power smoothly from one pulley to another.

Their strength lies in simplicity, flexibility, and cost-effectiveness. While gear or chain systems may need heavy maintenance, a flat transmission belt can run efficiently for years with minimal care.

Understanding Flat Belt Drives

A flat belt drive is a power transmission unit that employs a flat, flexible belt to transfer energy between two rotating shafts. The belt is drawn over the pulleys in a continuous loop, thus providing uniform movement and consistent energy flow.

Flat belts are generally constructed of rubber, leather, or synthetic materials and are suitable for operations with low and medium torques. Due to the smooth and wide belt surface, the drive allows quiet and vibrationless operation – excellent for devices in which accuracy and low noise are required.

When paired with the right pulley alignment, flat transmission belts can handle long-distance drives efficiently, making them a simple yet effective choice for industrial motion systems.

Advantages of Flat Belt Drives

Industries continue to use flat belts despite technological development because they provide feasible advantages:

- High efficiency: Due to the low friction, the energy loss is very minimal during the whole process.

- Flexibility: The belt can be used even if there is more than one pulley, and the distance is quite long without any problem.

- Quiet performance: Because there is less vibration, the machines can operate quietly and at a steady pace.

- Easy maintenance: They can be easily installed and require less maintenance than other drive systems.

- Safety: In case of overload, the belt slips slightly instead of breaking — protecting both machine and operator.

While V-belts are great for compact, torque-heavy setups, flat belt drives remain the go-to solution when speed, smoothness, and efficiency are top priorities.

Modern industrial flat belts are also more durable, using advanced synthetic materials that extend lifespan and reduce downtime.

Common Industrial Applications of Flat Belts

Flat transmission belts are everywhere – from traditional workshops to advanced automated lines. Their smooth performance and steady grip make them a preferred choice across many industries.

Some of the most common applications include:

- Textile machinery: Ensures consistent motion for spinning, weaving, and winding.

- Paper mills and printing units: Delivers uniform speed and precision during production.

- Agricultural and packaging machinery: Provides reliable power transfer even with changing loads.

- Machine tools and conveyors: Offers clean, quiet operation in continuous processes.

Modern industrial flat belts are made with advanced compounds like polyurethane and synthetic rubber, giving them higher wear resistance and better flexibility, which is ideal for long hours of uninterrupted use.

Flat Belt Maintenance: Best Practices for Long Life

Like any mechanical part, a flat belt performs best with regular care. Following a few simple steps can extend its life and keep your machinery running smoothly:

- Inspect regularly: Check for cracks, glazing, or hardening.

- Adjust tension correctly: Too loose causes slippage; too tight leads to early wear.

- Keep it clean: Dust or oil can reduce grip and increase friction losses.

- Align pulleys: Misalignment causes uneven wear at the belt edges.

- Lubricate carefully: Keep oil away from the belt surface; only lubricate bearings.

Common Flat Belt Issues to Watch For:

Misalignment, belt slippage, and surface glazing are early signs that maintenance or replacement is due. Preventive checks save both cost and downtime.

How to Choose the Right Flat Belt for Your Application

Choosing the right flat transmission belt is as important as maintaining it. A few key points can help:

- Load and speed: Match belt material and thickness with power requirements.

- Environment: Consider temperature, dust, and chemical exposure.

- Pulley setup: Check diameter, spacing, and surface condition for proper fit.

- Material selection: Use synthetic belts for high durability; rubber belts for affordability.

And most importantly, work with a reliable supplier. Partnering with Jigna Sales ensures you get quality-tested belts, expert guidance, and quick replacements when needed – helping your machines perform without interruptions.

Reliable Motion, Simplified

Flat belt drives may look simple, but they’re essential to countless industrial systems. Their mix of efficiency, durability, and easy maintenance keeps operations running smoothly day after day.

From light-duty machines to high-speed industrial setups, these belts deliver the right balance of speed and reliability.

At Jigna Sales, we’re proud to continue supporting industries with flat transmission belts that stand for quality, consistency, and dependable performance – built for the motion that never stops.

Keep your machines moving efficiently. Connect with Jigna Sales to get durable, precision-made flat transmission belts built for industrial performance.