In this blog, learn how industrial belts impact manufacturing plant efficiency, covering their role in minimizing downtime and ensuring reliable performance.

In manufacturing, each decision influences efficiency, costs, and the final output. Among the many components that contribute to smooth operations, industrial belts are crucial in ensuring machinery runs as it should. These belts help transfer power between various parts of machines, making it possible for equipment to work together seamlessly. In a plant environment, even a small malfunction can have a large impact on productivity, which is why choosing the right industrial vee belts and other industrial belts is vital.

Key Takeaways

- High-quality industrial belts last longer, reducing the need for frequent replacements. This lowers overall maintenance costs in manufacturing plants.

- Reliable industrial vee belts keep machinery running smoothly, preventing unexpected breakdowns. Less downtime means higher productivity.

- Quality industrial belts ensure optimal power transfer, boosting machine performance. Efficient equipment leads to reduced energy costs and better output.

- Well-made industrial belts reduce the risk of machine malfunctions. This ensures a safe working environment for all employees.

The Role of Industrial Belts in Manufacturing

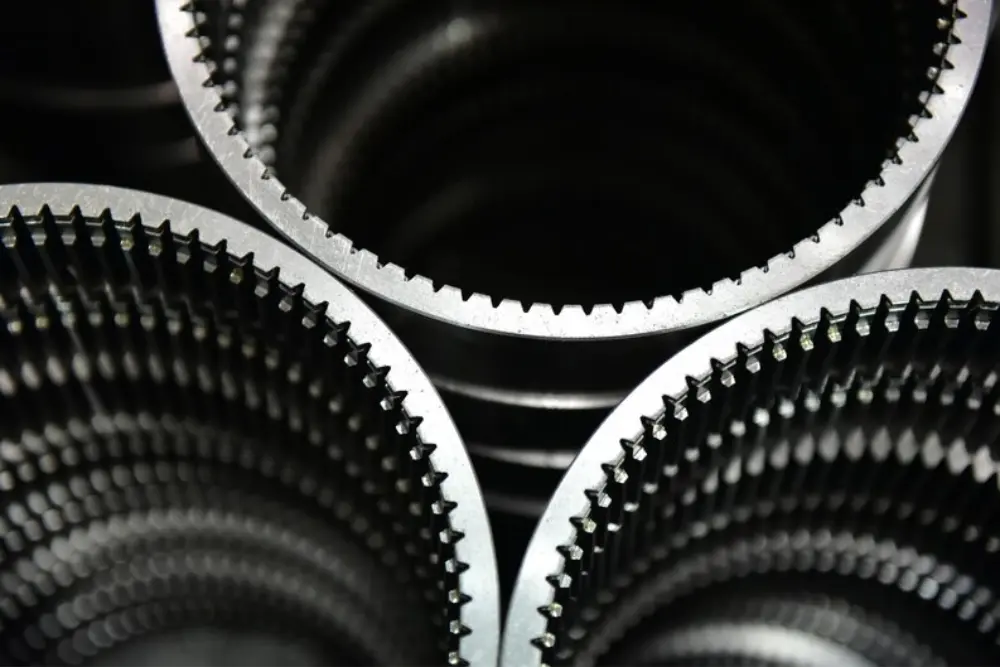

At the heart of most industrial processes is the transmission of power. Industrial belts are responsible for carrying mechanical energy from one machine part to another. From conveyor systems to pumps, motors, and other essential machinery, industrial belts are the unsung heroes of production. Industrial vee belts are one of the most commonly used types of industrial belts. Their design allows them to handle high power loads efficiently, making them perfect for industrial machinery. These belts are used to transfer energy and drive mechanical systems, ensuring that equipment runs at optimal performance.

However, belts endure constant wear and tear from ongoing movement and friction. If a belt fails, it can bring the entire manufacturing process to a halt, resulting in downtime, repair costs, and loss of production. That is why the quality of industrial belts is so important. High-quality belts can last longer, perform better, and provide the reliability needed to keep operations running smoothly.

Why Quality Matters for Industrial Belts

- Durability and Longevity

A high-quality industrial belt is built to last. In manufacturing plants, machinery operates under tough conditions, and belts are often subjected to heavy loads, extreme temperatures, and constant motion. A durable belt ensures that the machinery it drives continues to perform efficiently over time. With low-quality belts, there is a higher risk of premature failure, which means frequent replacements and costly repairs. High-quality belts, however, can last much longer, offering greater value in the long run. Durable belts also reduce maintenance costs. Since they do not need to be replaced as often, plant managers can save on labor costs and minimize downtime associated with maintenance.

- Minimizing Downtime

Downtime is among the most expensive hurdles faced in manufacturing. When machinery breaks down, production halts, and this leads to significant losses in both time and money. One of the leading causes of machinery failure is poor-quality industrial vee belts. A belt that stretches, slips, or breaks can cause major disruptions in the manufacturing process.

By investing in high-quality industrial belts, plants can reduce the risk of unexpected breakdowns. Well-made belts are less likely to fail, keeping production running smoothly and minimizing the risk of downtime. This, in turn, helps plants meet production goals, maintain customer satisfaction, and avoid costly delays.

- Better Efficiency

The key purpose of industrial belts is to ensure efficient power transmission. A well-functioning belt allows machines to work at their peak, without wasting energy or power. High-quality belts ensure smooth power transfer, which improves the overall efficiency of the equipment.

In contrast, poor-quality belts can lead to slippage, friction, and energy loss. This means that machines must work harder to achieve the same results, which leads to higher energy consumption and reduced performance. High-quality industrial belts, on the other hand, contribute to lower energy costs, making them more environmentally friendly and cost-effective in the long term.

- Safety

In manufacturing settings, prioritizing safety is non-negotiable. Poor-quality industrial belts can fail unexpectedly, causing machines to malfunction or even break. These malfunctions can lead to accidents, posing a serious safety risk to workers.

Quality industrial belts, however, are designed with safety in mind. These belts are built to withstand the pressures of industrial environments, reducing the chances of failure. With less frequent breakdowns, plant operators and workers can feel more secure in their daily tasks. Using high-quality belts ensures that the machines are functioning properly, reducing the risk of injury caused by equipment malfunctions.

- Cost-Effectiveness

While high-quality industrial vee belts might come at a higher price initially, their performance and durability make them a more cost-effective choice in the long run. Cheaper belts may seem like an attractive option at first, but their frequent failures can lead to higher maintenance costs, downtime, and replacements. Investing in quality belts eliminates these issues, saving the company money over time.

In addition to reducing the need for replacements, high-quality industrial belts contribute to overall efficiency, leading to lower energy costs. With energy savings and fewer breakdowns, manufacturers will see an impressive return on investment in the form of improved productivity and lower operational expenses.

Choosing the Right Industrial Belt Manufacturers

Selecting the right industrial belt manufacturers is just as important as choosing high-quality belts. Manufacturers with a proven track record of producing reliable, durable belts will help ensure that your equipment operates at peak performance. It’s important to choose a manufacturer that uses high-quality materials, advanced manufacturing processes, and strict quality control standards.

Working with trusted manufacturers will provide access to a range of industrial belts, including industrial vee belts, that are suitable for your plant’s specific needs. Whether you are looking for belts to power conveyors, pumps, or other industrial machinery, the right manufacturer will help you find the perfect solution. Before making a purchase, take into account the unique needs of your equipment. Each type of belt serves a different purpose, and the right choice depends on factors such as load capacity, operating conditions, and belt design. Reputable manufacturers can help guide you in selecting the best belt for your plant’s operations.

“The quality of industrial belts directly affects the efficiency, productivity, and safety of manufacturing plants. High-quality belts ensure that machinery operates smoothly, reducing downtime, maintenance costs, and energy consumption. Investing in reliable industrial vee belts and working with trusted industrial belt manufacturers is essential for improving plant performance and ensuring long-term success.

For those looking for durable, reliable industrial belts, Jigna Sales offers a range of high-quality products designed to meet the demands of modern manufacturing. At Jigna Sales, we pride ourselves on being a trusted supplier of top-quality industrial belts. Our products are built for durability and performance, ensuring your machinery operates efficiently and without interruption. With our range of premium industrial belts, we’re here to support your manufacturing needs.

Let’s make your machinery run smoother with our top-quality industrial belts. Get in touch with us today and let’s find the perfect solution for your needs.”