What are Timing Belts?

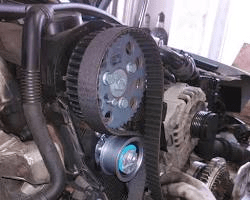

Timing belts, also known as cambelts, function as timing chains in engines featuring larger bores and strokes. They play a crucial role in the operation of internal combustion engines by synchronizing the rotation of the camshaft and crankshaft.

When these two components are in harmony, the valves and pistons operate in proper sequence. In practical terms, this synchronization ensures that the valves regulate the intake and exhaust of air and fuel mixture, while the pistons are appropriately pushed down as the fuel ignites in the combustion chamber.

Related article: WHAT IS A TIMING BELT AND WHAT IS IT USED FOR?

Design of Timing Belts ( Timing Belt Teeth, Timing Belt Tooth Profiles, )

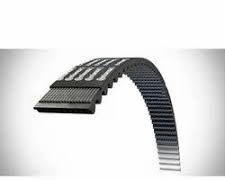

Timing belts consist of two primary components:

- Molded cords within the belt that carry the torque load,

- A plastic compound used for shaping the teeth and covering the cords.

These timing pulley belt components are crafted from various materials to suit different types of timing belts based on their intended use.

The selection of materials is influenced by the end application of the belt. Typically, industrial timing belt cords are constructed from materials like fiberglass, and polyester, each offering unique properties.

These cords play a crucial role in transmitting power within the drive system through the belt.

Timing Belt Teeth

Reliable timing belt teeth play a crucial role in maintaining synchronization between the crank and camshafts.

These teeth come in a variety of metric pitches, with a pitch representing the distance from the center of one tooth to the center of an adjacent tooth on the timing belt.

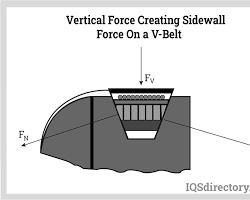

Pitches significantly impact factors such as the number of teeth and diameter on timing pulley belts. While older industrial timing belts feature trapezoidal-shaped teeth, advancements in manufacturing now allow for curved teeth, addressing common challenges with noise and lifespan associated with trapezoidal designs.

It’s worth noting that an industrial timing belt with a reduced width enhances performance by reducing weight and friction.

- Trapezoidal belt tooth

Trapezoidal belt tooth profiles are extensively utilized in industrial timing belt-related applications, particularly for linear positioning and conveying.

While they offer good force transmission and low backlash, the trapezoidal tooth shape can lead to high wear rates in high-torque or high-speed scenarios due to stress concentrations at the belt-pulley interface.

- Curvilinear belt tooth

Curvilinear belt tooth profiles were developed to address stress concentrations in trapezoidal profiles, enhancing torque and speed capabilities.

With larger tooth depth and smoother mesh transitions, curvilinear profiles are quieter than their trapezoidal counterparts. However, they come with a tradeoff of higher backlash.

- Modified curvilinear tooth

Modified curvilinear tooth profiles further refine the curvilinear design, featuring a smaller tooth depth and greater flank angle.

This modification grants the highest torque and force transmission capabilities, minimizing the likelihood of ratcheting even under extreme loads.

Common in processing applications requiring high-torque transmission at high speeds, belts with modified curvilinear teeth excel in load-sharing between engaged teeth and the belt areas, ensuring robust performance.

Stages in Designing a Timing Belt

Jigna Sales is committed to being the foremost manufacturer of industrial timing belts. This brief guide aims to assist you in designing timing belts for your application.

Feel free to reach out to us for any needed support. For unique applications, our knowledgeable engineering and sales staff are available to provide technical assistance.

STEP 1: Determine the peak torque for your drive, typically the motor starting torque. Account for any unusual momentary or shock loads during normal operation.

STEP 2: Identify the largest pulley diameters considering space limitations and drive ratio. This enhances torque capacity and extends the timing pulley belt service life.

STEP 3: Select the timing belt tooth profile (contact us for advice if needed). If the peak drive torque is close to the torque transmission limit for the chosen profile, consider using the next higher torque-rated profile. Determine the corresponding pitch for the selected profile, crucial for calculating the required number of timing belt teeth.

STEP 4: Calculate the Teeth in Mesh (T.I.M.), considering the Teeth in Mesh factor. Divide the peak torque (from Step 1) by the T.I.M. factor to ascertain the design torque.

IMPORTANT: Recheck the timing belt pitch to ensure this torque adjustment has not exceeded the limits of the desired pitch for your chosen timing pulleys.

STEP 5: Compute the belt pitch length based on the design center distance of your drive.

STEP 6: Divide the timing belt pitch length by the selected tooth pitch, rounding the result to the nearest whole number. This yields the number of teeth on the timing belt for your application. Adjust the nominal center distance of your drive design to match the belt.

STEP 7: Calculate the effective tension (Te) on the drive using the pitch radius and design torque of the smallest loaded pulley in the system.

STEP 8: Choose the strength factor for your application. Divide the effective tension from Step 7 by the strength factor to determine the required break strength for the belt design. Multiply by 2 for a double-span break.

Refer to the break strength table to decide the necessary reinforcement type and belt width. Ensure the listed value in the table surpasses the design break strength.

STEP 9: Select a rubber timing belt width capable of handling the design torque with the chosen pulley size. Note: This belt width may differ from the width selected in Step 8. The required belt width for the system will be the wider of the two.

Timing Belts Construction Material ( Rubber in Timing Belts, Polyurethane Material, Fabric Belts, )

Timing belts are available in various types, each tailored to specific applications, and crafted from specific materials optimized for particular environments.

When selecting an industrial timing belt for a specific application, it’s essential to consider the material it is made from to ensure optimal performance.

Timely and careful replacement of a timing belt is critical to maintain the efficiency and reliability of the system it operates in.

Polyurethane material

Polyurethane has gained popularity as a preferred material for timing belts owing to its notable properties, including resistance to high temperatures, inherent elasticity, and resilience against the detrimental effects of oil.

Timing belts crafted from polyurethane prove to be durable and provide highly energy-efficient solutions for a diverse range of applications.

Fabric Belts

Fabric belts, ideal for applications demanding high performance and acceleration forces, offer a versatile solution.

These industrial timing belts incorporate various materials, resulting in impressive tensile strength, low coefficients of friction, and excellent resistance to high and low temperatures.

In scenarios where high torque or acceleration is essential, a diverse range of fabric timing belt options is available to meet and greatly benefit specific requirements.

Rubber

Rubber stands out as the predominant construction material for timing belts, widely utilized across various industries and applications.

Many internal combustion engines in diverse vehicles rely on timing belts crafted from rubber or rubber compounds. However, traditional rubber timing belts are susceptible to stretching and breakage, particularly in high-temperature environments with substantial motor oil present in engine blocks.

Advancements in technology have led to the development of temperature-resistant rubber materials, enhancing the durability of rubber timing belts and improving their resistance to distortion.

These modern rubber formulations contribute to prolonging the lifespan of rubber timing belts.

The function of Timing Belts

The timing belt is a crucial component that regulates the camshafts in your engine, orchestrating the precise opening and closing of valves for optimal performance.

Equipped with teeth, the timing belt synchronizes the crankshaft with the crankshaft.

Although some vehicles rely on more durable timing chains or gears, timing belts, crafted from a rubber compound, offer the advantages of quieter operation and increased efficiency.

Additionally, they operate without the need for lubrication.

In certain engines, a failure of the timing belt can result in valves being improperly held open, leading them to collide with pistons and causing severe damage to the engine. Consequently, preventing such failures is imperative.

When replacing the industrial timing belt, it’s prudent to consider replacing the water pump as well. Water pumps share similar lifespans and accessing them during the timing of pulley belt replacement is convenient. Delaying this replacement could result in higher installation costs down the road.

Types of Timing Belts and Their Failure

- Open Ended Timing Belts

Open-ended timing belts featuring diverse tooth designs serve as a highly effective alternative for converting synchronous rotational movement into linear motion.

This presents an economical, noise-free, and maintenance-free solution for oscillating or linear drives, achieved by connecting the ends using our clamping plates.

The outcome is the optimization of positioning accuracy, repeatability, and power capacity. Within the category of open-ended timing belts, the AT10 or AT15 move-series distinguishes itself as the most rigid and robust option.

These belts are conveniently offered in 50m rolls or can be provided in specified cut lengths as needed.

Utilizing the same extended-length belting, we offer tailor-made belts spliced to any required length. Whether it’s one tooth longer or shorter than an available mold size, or a belt spanning several hundred feet, we can accommodate your needs.

This proves to be an exceptional option for applications such as synchronous conveying, indexing, automation, and packaging.

The process provides the flexibility to manufacture a single piece for prototyping without the necessity for costly tooling or in large production quantities.

Additionally, it’s important to note that we can apply any of the available backings to the belt.

- Spliced and Welded Timing Belts

Timing belts that are spliced and welded are well-suited for general-purpose applications, particularly in conveying and applications with welded profiles and backings.

The manufacturing process involves starting with a length of open roll stock featuring finger splices that are subsequently heat-welded together.

These belts offer sealed edges and a smooth back, similar to open-ended timing belts.

As a result of the welding process, they possess 50% of the strength of truly endless belts and are available for purchase in one-tooth increments to meet specific length requirements.

- Truly Endless Timing Belts

Endless belts, devoid of seams or splices that might be prone to failure, offer a seamless and well-balanced construction that promotes smooth operation, reducing vibrations and minimizing strain on the system.

These continuous belts play a vital role in material transportation during the production process.

The term “endless” signifies the absence of seams or joints in these belts. Typically crafted from rubber materials such as urethane, neoprene, or nitrile, they come in diverse dimensions and surface profiles.

Key characteristics of endless belts include their elasticity, durability, and resistance to abrasions and chemicals.

Failure of a Timing Belt

Industrial timing belt manufacturers recommend specific distances or time intervals for timing belt replacement.

Failure to replace the timing belt on schedule can lead to a complete breakdown or catastrophic failure of the engine, particularly in interference engines.

To determine the appropriate replacement intervals, owners should refer to the manual maintenance guidelines provided by the manufacturer.

Typically, replacement is recommended every 30,000 to 50,000 miles to ensure the continued smooth operation and longevity of the engine.

Causes of Timing Belt Failure

- Running Noises from Belt

When encountering running noises emanating from the belt, a probable diagnosis is excessive tension, manifesting as a whining or whistling sound.

The recommended solution involves adjusting the tension to an appropriate level for optimal performance.

- Edge Wear

In cases of edge wear, a potential diagnosis is the belt not being parallel to the axis, causing it to run against the flanged pulley.

Additionally, flaws in the flanged pulley could contribute to this issue. To address these concerns, it is recommended to inspect the drive system, ensuring proper alignment of pulleys.

If misalignment is detected, adjustments should be made or, if necessary, non-aligned pulleys should be replaced, along with changing the belt.

Furthermore, replacing the idler/tensioning pulleys and the belt is advised as a solution to rectify edge wear caused by pulley-related issues.

- Timing Belt Snaps

In instances where the timing belt snaps, a potential diagnosis points to the presence of foreign matter in the drive.

The recommended solution involves removing the foreign matter or media and subsequently replacing the belt.

Additionally, if contact with foreign media is identified as the cause, it is advised to change the timing belt and verify that the covering is appropriately seated to ensure optimal performance.

- Teeth and Fabric Separating from Belt Body

When teeth and fabric start separating from the belt body, a likely diagnosis is the presence of leaks in the engine or engine compartment, such as oil or antifreeze escaping.

To address this issue, it is recommended to undertake the necessary repairs to fix the leaks and subsequently replace the industrial timing belt for optimal functioning.

Symptoms of a Failing Timing Belt

- Engine Failure to Start

When your engine refuses to ignite, it’s clear that something is amiss, yet pinpointing the issue can be a challenge.

Surprisingly, a worn-out timing belt could be the culprit. In this case, you might hear the starter motor engage when the ignition is on, even though the engine refuses to turn over.

Unfortunately, if the timing belt is the cause, your engine may already be damaged at this stage. We strongly advise contacting your mechanic promptly.

If you find yourself stranded on the road or in a parking lot, consider reaching out to your insurance company for assistance. If you’re not insured, a call to arrange towing to the mechanic would be a prudent step.

- Engine Irregularities Between 2,000 and 4,000 RPM

If your vehicle experiences sluggish acceleration within the 2,000 to 4,000 RPM range, accompanied by a sense of reduced power or unusual rattling sounds during revving, it might signify a loose or aging timing belt.

The presence of timing belt slippage during high RPM acceleration could further indicate that the timing belt is deteriorating, potentially with missing teeth.

In such cases, seeking immediate attention from your mechanic is strongly advised.

Applications and Advantages of Timing Belts

Applications of Timing Belts

- Automobile Timing Belt:

A prime illustration of a real-life timing belt drive system is the timing belt/cam belt system found in the majority of automobiles globally.

The efficiency of these robust automobile timing belts is a cornerstone of modern-world mobility. These toothed timing belts, used in automotive applications, are high-performance, often crafted from special materials.

They synchronize the rotational motion of the engine crankshaft with the camshaft, ensuring the precise opening and closing of intake/exhaust valves during the combustion process.

This synchronization, akin to the engine’s pacemaker, is crucial for sustaining combustion.

These timing pulley belts demand an exceptionally high level of synchronicity and must withstand high rotational speeds, reaching thousands of RPMs, as evident in typical driving conditions.

Moreover, they must exhibit resilience in extreme temperature ranges, spanning hot deserts to cold tundras.

The fatigue life of these belts is paramount, requiring high wear resistance to ensure safe operation for thousands of miles.

- Treadmills

The treadmill serves as a notable example of a belt-driven mechanism. In this system, the industrial timing belt refers to the toothed, synchronous belt that facilitates the transfer of rotary motion from the central motor to the drive pulley.

This drive is typically positioned at the rear of the treadmill, although front placement is also possible. While these drives are generally high-performance, toothed synchronous belt systems, older treadmill models might feature flat friction belts or V-belts.

These timing pulley belts must efficiently endure the continuous shock loading caused by the runner’s foot striking the tread.

In the face of dynamic loading conditions, the belt drive must maintain a consistent speed profile without slipping.

Advantages of Timing Belts

Here are the noteworthy advantages of timing belts:

- Precise timing, maintaining high torque capability. Minimal vibration, slip-proof engagement, and wide speed range.

- Virtually no elongation due to wear, offering up to 98% mechanical efficiency.

- Clean, lubrication-free operation with reduced noise.

- Long, trouble-free service, excellent abrasion resistance, rust resistance, and chemical resistance.

- Offers diverse drive design options, weight savings, and safety benefits.

- Economical with no need for expensive enclosures, lubrication systems, or ongoing maintenance costs.

- Energy-efficient, reducing downtime and associated costs.

Considerations When Choosing a Timing Belt

Various applications require different types of timing belts, each designed to meet specific needs. These belts come in a range of dimensions and tooth profiles.

To effectively choose the right timing belt for your application, it’s crucial to understand the principles of belt sizing and selection tailored to different drive system types. You can talk to our experts.

Conclusion

Timing belts are available in a variety of types, each tailored to specific applications and constructed from materials optimized for particular environments.

When selecting a timing belt for a specific application, it is crucial to consider the material it is made from to ensure optimal performance.

This consideration ensures that the timing belt performs at its best in the chosen application. Additionally, timely and careful replacement of a timing belt is critical for maintaining efficient and reliable operation.

FAQ

What is the timing belt?

Timing belts, also known as cambelts, serve as timing chains for engines characterized by larger bores and strokes.

These rubber timing belts play a crucial role in the functionality of internal combustion engines by synchronizing the rotation of the camshaft and crankshaft.

When these components operate in harmony, the valves and pistons function correctly, contributing to the overall performance of the engine.

What is the structure of a timing belt?

A timing pulley belt comprises two primary elements: molded cords housed within the belt responsible for carrying the torque load, and a plastic compound utilized for shaping the teeth and covering the cords.

These components are crafted from various materials, and tailored to suit the specific requirements of different types of timing belts.

What is the function of a timing belt?

The industrial timing belt is the component that regulates the camshafts in your engine, ensuring the precise opening and closing of valves at optimal moments for smooth operation.

Equipped with teeth, the timing belt synchronizes the rotation of the camshaft with the crankshaft. While some vehicles employ more durable timing chains or gears, the timing belt remains a common feature in many cars and trucks.

What are the different types of timing belts?

Timing belts utilize a variety of materials, each with unique specifications tailored to specific circumstances. As mentioned earlier, these materials encompass urethane, neoprene, rubber, fabric, and more.

What are the major causes of timing belt failure?

Industrial timing belt failures can result from various issues, including running noises, edge wear, fabric wear in the tooth root, unacceptable wear of tooth flanks, base separating, tooth shearing, teeth, and fabric separating from the belt body, running marks on teeth side, cracks on the back of the timing belt, and timing belt snaps.

Diagnosing these problems is crucial. Solutions involve addressing specific causes such as adjusting tension, aligning pulleys, repairing leaks, and replacing the belt.

Regular inspection and maintenance are essential to prevent these issues and ensure the reliable operation of timing belts in automotive applications.

What is the application of a timing belt?

Timing belts facilitate the functioning of a vehicle’s engine by connecting the camshaft to the crankshaft. Their role extends to controlling the movement of pistons and valves within the vehicle.

In simpler terms, a timing belt can be likened to a reinforced rubber band with teeth or notches on the inner side, ensuring synchronized and precise engine operation.

What is the advantage of a timing belt?

Accurate timing for precise motion. Minimal maintenance and cleanliness in operation. Consistent velocity ratio without any slippage.

How do I choose the right timing belt?

To determine the type of timing belt in use, start by examining the identifying numbers or letters marked on the belt.

These alphanumeric markings signify a standard trade size and play a crucial role in pinpointing the details of the cog belt.

When opting for a timing belt for a specific application, it is crucial to consider the build material to ensure optimal performance.

This consideration ensures that the timing belt performs at its best in the chosen application. For additional guidance, feel free to contact us for expert advice on the design process.